Nowaste Logistics, a Swedish third-party logistics (TPL) provider, has ordered a second robot picking cell from Cognibotics following the successful pilot of its first installation. Integrated with Nowaste’s AutoStore system delivered by Swisslog, the Cognibotics robot cell enables high-speed picking directly from AutoStore ports, supporting scalable, robust, and future-ready automated order fulfilment while strengthening Nowaste’s service offering to TPL customers.

The Cognibotics material-handling robot, equipped with Sics.AI’s vision system, has been operating in production at Nowaste with stable performance and reliable uptime. Based on these results, Nowaste is expanding robotised picking as a strategic component of its warehouse operations. Patrik Johnfors, Head of Implementation and Solution Design at Nowaste Logistics, notes that the first cell demonstrated the ability of robotised picking to handle a diverse product assortment while delivering the robustness and stability required for TPL operations. He adds that deploying a second cell is a clear strategic step, improving resilience during seasonal peaks and helping future-proof operations as customer demands evolve.

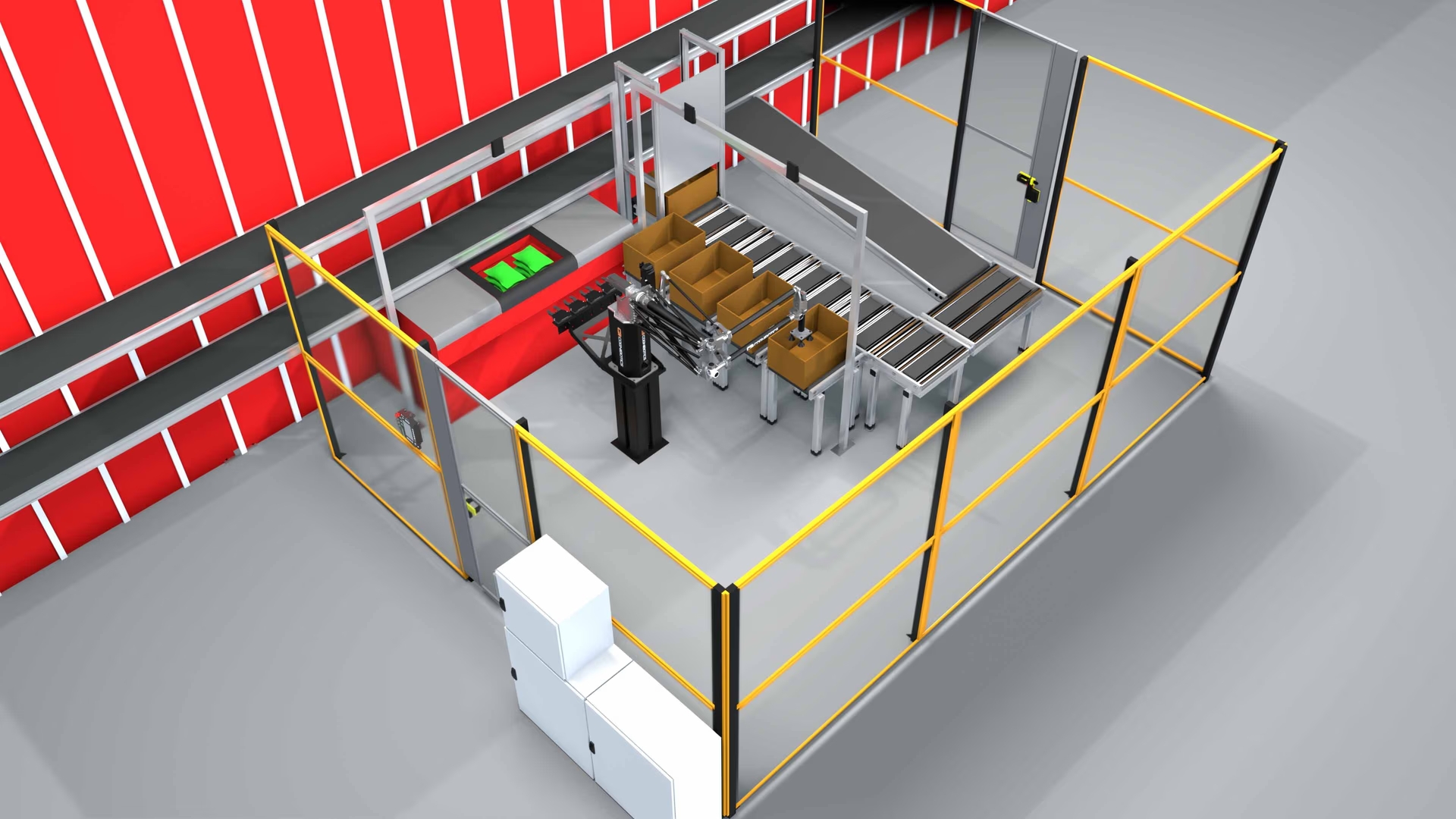

For TPL providers, the picking cell highlights the importance of reach and speed in delivering high and consistent picking capacity. Its design allows multiple presentations, totes, and hand-off points to be placed within reach, supporting flexible layouts, efficient batching, and smooth handling of mixed product flows. Capacity can be scaled incrementally by adding robot cells without reconfiguring existing infrastructure. Fredrik Malmgren, CEO of Cognibotics, says Nowaste exemplifies how modern TPL providers use robotisation to enhance robustness, capacity, and layout flexibility. He adds that the second order marks a milestone for Cognibotics, as it is the first time its Juliet & Romeo software automation foundation is running in full production on a material-handling robot cell, proving its readiness to scale in real-world logistics environments.

Within the AutoStore setup, the Nowaste picking cell combines Cognibotics’ high-speed, long-reach robot with advanced AI vision capable of handling a wide and varied product mix. Powered by the Juliet & Romeo automation foundation, the system manages real-time robot motion, gripping, and conveyor hand-off while simplifying integration with Nowaste’s warehouse management and control systems. By using a software-defined motion platform, Cognibotics enables Nowaste to adapt layouts, product flows, and item types over time without hardware redesign—an essential capability for TPL providers serving multiple customers with evolving needs.