Yokogawa Electric has entered into a long-term agreement with Shell Global Solutions to co-develop and deploy advanced robotics and drone technologies for plant monitoring and maintenance. The collaboration aims to enhance operational safety, efficiency, and automation in industrial facilities.

As part of the agreement, Yokogawa will integrate Operator Round by Exception (ORE)—an advanced machine vision solution developed by Shell—into its OpreX Robot Management Core software platform. This enhanced solution will be made available to customers across the energy, chemicals, and broader industrial sectors.

ORE leverages machine vision and AI analytics to enable robots to autonomously execute operator round tasks, such as reading analog gauges, detecting leaks, and identifying mechanical anomalies. The technology was developed over two years within Shell, drawing on the company’s expertise in integrity management, remote inspections, and corrosion detection.

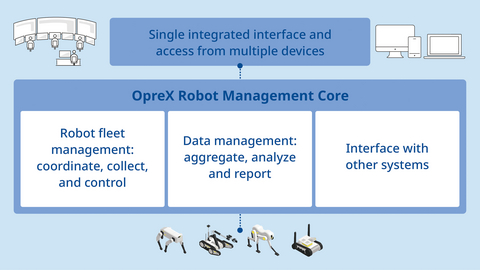

Yokogawa’s OpreX Robot Management Core serves as a central management system for various plant robots. By integrating with plant control and safety systems, it allows facilities to issue instructions to robots, enabling a shift toward autonomous plant operations. With the addition of Shell’s ORE, the platform’s range of supported use cases will expand significantly.

Pilot deployments of the integrated robotics solution are planned for two Shell facilities, exploring how autonomous technologies can improve efficiency and safety in real-world industrial settings.

This marks a key milestone in Yokogawa’s involvement at the Energy Transition Campus Amsterdam, a collaboration hub established by Shell in 2022. The campus brings together companies, governments, universities, and societal organisations to accelerate development of next-generation energy solutions.

Yokogawa and Shell have also committed to a joint R&D roadmap to further enhance the machine vision technology, with a focus on continuous innovation and expanding real-world applications.

Masaharu Maeda, Vice President and Executive Officer at Yokogawa and Head of the Solutions Business Division, stated:

“We are very excited to work with Shell on this transformative technology. It has the potential to address workforce challenges by increasing field efficiency and reducing risk to personnel. We look forward to delivering this solution to industrial operators globally.”

Gerben de Jong, Chief Information Officer for Shell Integrated Gas, Upstream, and Projects & Technology, commented:

“Shell and Yokogawa have a longstanding partnership in advancing automation. This new agreement takes that collaboration to the next level. By combining robotics with AI, we have the opportunity to significantly boost productivity and enhance site safety.”