Siemens and Japanese machine builder Hirano Tecseed have joined forces to modernize battery manufacturing through a collaborative effort focused on standardization and digitalization.

The partnership aims to optimize battery coating processes—critical to the performance and durability of lithium-ion batteries—by enhancing efficiency, reducing waste, and improving product quality and operator effectiveness.

Driving Innovation in a Rapidly Growing Market

With the accelerating global shift toward sustainable energy, fueled by the rise of electric vehicles and large-scale energy storage systems, demand for high-quality battery manufacturing is surging. Machine builders like Hirano are under increasing pressure to scale production while minimizing costs, all without compromising on quality or safety.

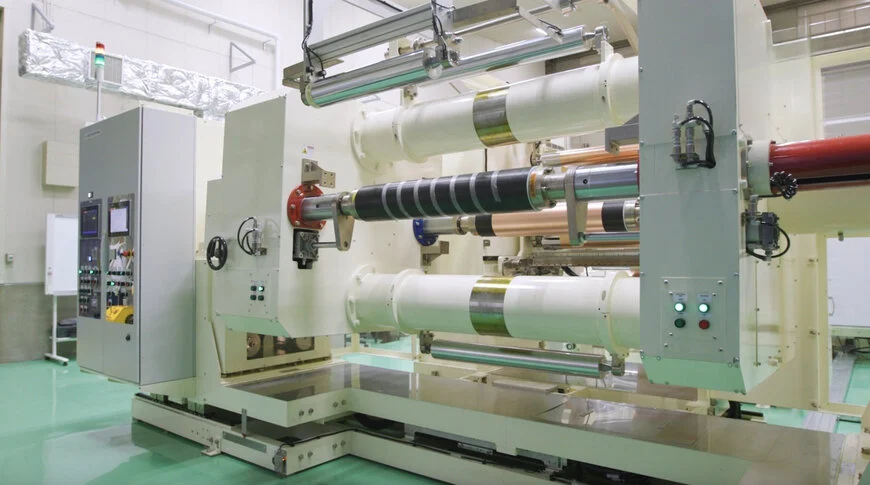

One of the most crucial stages in battery production involves coating foil strips with multiple active material layers to form electrodes. Any imperfections in this process can significantly impact the final product’s performance, making precise control of speed and tension during coating essential.

Harnessing the Power of the Digital Twin

At the heart of the Siemens-Hirano partnership is the development of a digital twin for battery coating machines. Leveraging Siemens’ Simcenter software, Hirano created a highly accurate virtual model of its battery coating equipment. The digital twin integrates real-time data from Siemens’ Simatic controllers and Sinamics drives, which automate the pilot machine, enabling real-world performance testing in a simulated environment.

Through Simcenter Amesim, a system simulation tool from the Siemens Xcelerator platform, Hirano’s engineers can assess and optimize the machine’s web handling system virtually—maximizing throughput and reducing trial-and-error in physical development.

Previously, machine parameters were set based largely on experience, which carried a risk of errors and product defects. With Siemens’ digital twin technology, Hirano can now configure and validate machine performance virtually before any physical build, reducing the reliance on prototypes and improving predictability.

The results are compelling: machine configurations can be evaluated and optimized five times faster in the virtual environment compared to traditional methods. Moreover, up to 80% of the digital twin and simulation model can be built using pre-configured, standard function blocks—accelerating implementation and commissioning while lowering development costs.

Executive Insights

Katsuhiro Omori, Director and Executive Officer of R&D at Hirano Tecseed, commented:

“We’re excited to collaborate with Siemens in redefining our battery manufacturing processes. Integrating mechatronics and automation simulation in a unified modeling environment has enabled us to identify potential product defects early and significantly advance our process optimization.”

Michael Thomas, Senior Vice President of Factory Automation and Head of Production Machines at Siemens, added:

“By combining our advanced simulation and automation technologies, Siemens is helping Hirano achieve new levels of efficiency and quality. This partnership highlights our commitment to empowering customers through innovation and driving digital transformation in the manufacturing industry.”

A Model for the Future of Manufacturing

This collaboration underscores how digital twin technology can play a pivotal role in next-generation battery production. As demand for sustainable energy solutions continues to grow, Siemens and Hirano Tecseed are setting a new benchmark for smart, efficient, and reliable manufacturing systems.